Spreading

Home > Spreading > Spreading fertilisers > Quality

Quality

Fertiliser has a major impact on the spreading pattern. It is therefore essential to check the quality of the fertiliser. The following three physical properties are important factors: fraction distribution, hardness and density. In addition, transport and handling have a major impact on the quality of fertilisers. A number of issues can be considered to ensure the best possible fertiliser quality.

The importance of checking

Mineral fertiliser has a major impact on the spreading pattern. Correct spreader settings and fertiliser quality are essential if a good spreading pattern is to be achieved. It is therefore very important to take a critical look at the quality of the fertiliser and check it thoroughly. Often farmers only focus on adjusting the settings on the fertiliser spreader. However, fertiliser quality affects the spreading pattern just as much.

Technical developments have greatly increased the working width of fertiliser spreaders.

When spreading large working widths, high-quality fertilisers should be used to prevent spreading paths. Mineral fertilisers are required to give their top performance, especially at working widths greater than 30 metres.

Impact of storage and handling

It is best to check each batch of mineral fertilisers on arrival. The quality of fertilisers may vary on delivery as it can deteriorate during transport, storage and handling. The reasons for this may include hardness deterioration, high moisture content or segregation.

Hardness deterioration is caused by conditions being unsuitable. Fertiliser segregation occurs when the large and small granules separate. This is most likely to occur in blends and fertilisers with a wide fraction distribution. The risk of segregation is especially high in bulk fertiliser storage.

Moreover, there may be differences in fraction distribution between batches of fertilisers from the same supplier. It is therefore advisable to perform some sieve fraction tests on each batch.

Maintaining quality

It is essential to check the quality of fertilisers during storage and before spreading. This is because storage on a primary farm can also have a major impact on the quality of fertilisers. The following aspects are important to ensure fertiliser quality during storage on the primary farm.

- Keep the silo moisture-proof, ensuring that the fill and vent pipe are sealed with caps;

- Always cover loose product with film;

- Do not store nitrate-containing fertilisers in the sun, do place them in the shade or indoors;

- Be careful when mixing different fertilisers;

- Do not keep residues in the spreader, but always empty the spreader after use.

“Handling and storage” contains more information on maintaining quality.

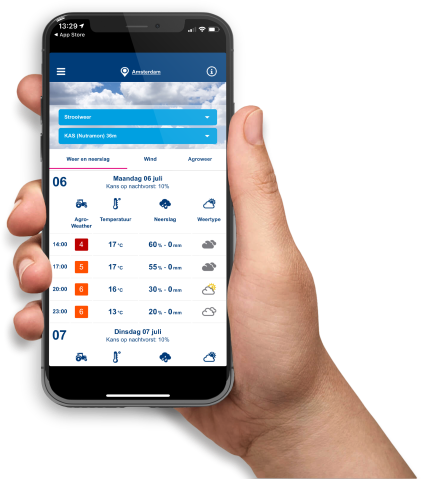

Checking quality based on physical properties

The physical properties of fertilisers are the defining characteristic for achieving a good spreading pattern. When checking quality, fraction composition, hardness and bulk weight are very important factors. These can be easily tested with a test kit as pictured here. You can easily check the fraction composition and bulk weight yourself using a fraction meter and a measuring cup. The necessary information can be found in the product specification sheets. This is more difficult in the case of hardness, because they do not normally specify

which hardness the granule has to conform to. If you

have any doubts relating to hardness, please contact the relevant fertiliser manufacturer.

This section briefly explains these three main physical properties.

Additional information on these and other physical properties is provided in “Physical Properties”.

Fraction composition

The fraction composition indicates the fertiliser’s granule size distribution. High-quality fertilisers contain a large percentage of granules of the same size. If the variation in granule size is too large or too small, the spreading pattern will be sub-optimal.

The fraction composition of mineral fertilisers can be measured using a grader box. Which fraction composition is correct will depend on the fertiliser used. To ascertain the correct fraction composition of the fertiliser, consult the spreading chart or contact your he fertiliser manufacturer.

Hardness

You can measure the hardness of a fertiliser with a hardness tester. When measuring hardness, it is essential to test enough fertiliser granules. You should therefore take a representative sample of sufficient size. Like the fraction composition, the right hardness varies from one fertiliser to another.

Bulk weight

Bulk weight is expressed as kg/l. You can measure the bulk weight by filling a measuring cup of exactly one litre capacity with fertiliser. The weight of the contents then constitutes the bulk weight. Which is the correct bulk weight will depend on the fertiliser. For example, the correct bulk weight of CAN varies between 970 and 1070 kg/m3 and the bulk weight of Urea, both granulated and prilled, is between 700 and 800 kg/m3.

Points to consider when checking quality

The following are important when checking the quality of fertilisers:

- Take a representative sample, i.e. a sufficiently large sample, mixing the fertiliser granules thoroughly. Depending on storage (in silo or in big-bags), large and smaller granules will separate.

- Conduct more shake tests and average out the results.

- Make sure you know how to use the necessary instruments (grader box, hardness tester). Read the manual before use and consult the manufacturer if in doubt.

- A quality check is important, but is merely indicative. It does not mean that in all cases the entire batch of fertiliser is of insufficient quality.

If the quality is lower than the guidelines, adjust the fertiliser spreader settings. This means the standard data listed in the spreading chart for the fertiliser concerned can no longer be used. In this case, look for a spreading chart for a fertiliser with the same or similar physical properties.

Sources:

Schriek R. v., 2012.

Smits, Strooien over het gewas vergt precisie, 2008.

Persson, 2014.