Spreading

Purchase

When purchasing a fertiliser spreader, it’s important to first consider the working width at which you want to spread. You can base your choice of working width on the most common plot width. The desired working widths must be complete widths in the spreading charts, and it’s also important to look at your regular fertiliser.

Next, you need to determine the hopper capacity which depends on the size of your farm. Besides the working width and hopper capacity, the following aspects are important considerations when purchasing a fertiliser spreader:

- Ease of operation and maintenance: operation should be straightforward and easy. In addition, components should be corrosion-resistant when in frequent use. Grease nipples should be easily accessible and the spreader should be easy to clean. Obtain an instruction manual that clearly explains the best way to adjust the spreader;

- Fill level: the fill level is important when using bagged material or a fertiliser silo. Space under the silo is often limited and loads should not be lifted too high when using bagged material. When filling a fertiliser spreader, it is also important that you can read the quantity indicated in the spreader;

- Possibility of turn-off test: this is done to check fertiliser application rate. The most practical test is one that does not involve removing parts;

- Spread accuracy: this is expressed as the coefficient of variation and can be measured by performing a spreader test. Besides the coefficient of variation, the maximum deviation is also important. The coefficient of variation is a measure of how evenly the fertiliser granules are spread. However, the coefficient of variation is also highly dependent on the quality of the fertiliser used. A coefficient of variation in excess of 15% is not acceptable;

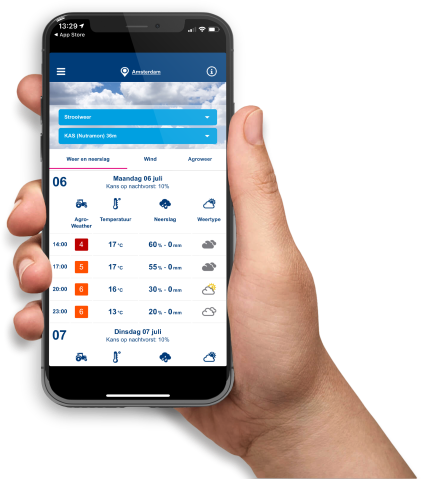

- Electronic measurement and control systems: many fertiliser spreaders are equipped with electronic measurement and control systems to ensure the accurate spread of mineral fertilisers. This includes systems that control the position of the metering slide during spreading. The amount of fertiliser is adjusted according to the driving speed, so the dosing remains the same. An electronic measurement and control system can be easily combined with GPS. These systems are set to play an important part in the efficient application of mineral fertilisers in future;

- GPS: nowadays, almost all new spreaders can be connected to the most commonly used GPS systems. When purchasing a spreader, think carefully about the type of systems you intend to use over time and in future;

- Boundary spreading: most spreaders are equipped with a system to accurately spread along field boundary areas. Several systems have been launched by manufacturers in recent years. What is important is that they should be easy to operate and preferably not require disassembly and assembly operations;

- Tractor lifting capacity: when purchasing a spreader, make sure that the tractor used for spreading has sufficient lifting capacity. In this case, the weight of the fertiliser spreader is the determining factor.

Points to be considered in a second-hand spreader

There are additional items to be taken into account when buying a second-hand spreader:

- Spreader discs and vanes: check to see whether the vanes are worn. The shorter the vane, the smaller the working width;

- Bearings: the disc bearings on a used spreader should be free of play;

- Instruction manual: check whether an instruction manual is supplied. If not, it is important to check whether the manual is available on the internet;

- Parts and accessories: always ensure that the necessary parts and accessories are supplied with the machines. This includes not only discs and vanes but also accessories needed for boundary spreading;

- Spreading charts: check that the spreading charts are available and up to date;

- Spreader test: after purchasing a spreader, it is advisable to carry out a spreader test.

Source:

Blanken, Middelkoop, Ouweltjes, Remmelink, & Wemmenhove, Handboek melkveehouderij, 2012.

Berg, 2013.

Broek, Kunstmeststrooiers: afstelling is alles, 2008.